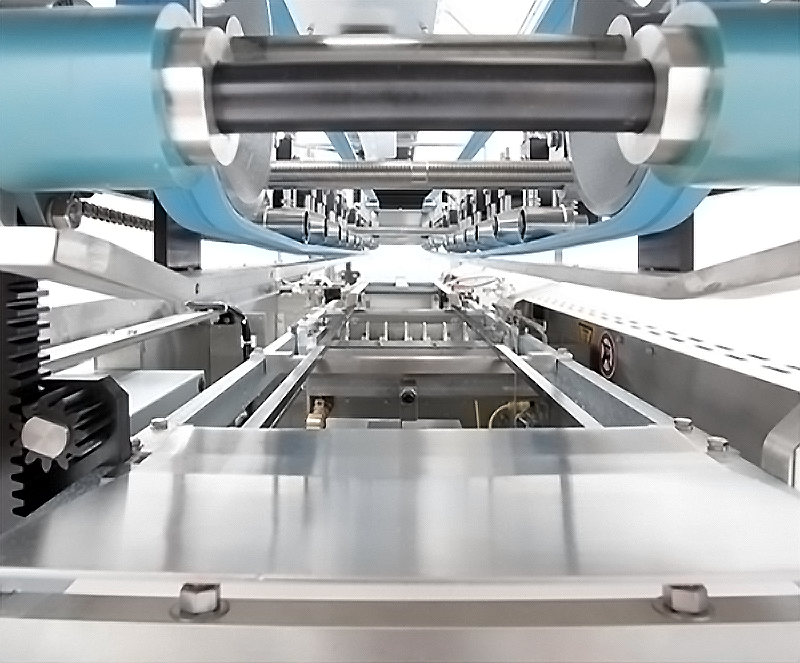

BURT Roll-Through Labeling Machines

Our efficient, adjustable BURT roll-through labeling machines are ideal for round containers. They are conceived for full-wrap labeling of cylindrical containers made from various material and of various volumes, these machines operate at speeds up to 600 containers per minute. With quick changeovers and the ability to replenish labels without stopping production, Burt labelers ensure precise, clean application and maximum flexibility for all your labeling needs.

Browse all the BURT labeling machines below.

Discover batch labeling or continuous labeling with the BURT labelers.

About BURT Roll-Through Labeling Machines

How does a BURT Roll-Through Labeler work?

A roll-through labeler is a cost-effective equipment to apply paper full-wrap labels to cylindrical containers. Like any other Labeling machine, the BURT Roll-Through has two infeed: one for the container, the other one for the labels. Once the round container is introduced to the machine with orizontal orientation, the glue is applied so that the label can stick and be wrapped around the container, after which the container is label and ready to be vertically oriented.

What types of containers can BURT label?

BURT Labelers can apply full-wrap labels to cylindrical containers made of virtually any material, including papers, foils, plastics, and laminates. As well as labeling containers serving different industries, from food, beverages and even aerosols. They can operate at speeds of up to 800 containers per minute (CPM) depending on the machine model, type of container and label.

How to ensure precise and clean Labeling?

The BURT Labeling machine uses a unique hydraulic feed system that smoothly and accurately positions labels. It also offers positive label pickup without glue slinging, ensuring a clean appearance. The BURT Roll-Through Labelers can also ensure continuous running of the machine with a second special infeed for labels, so that the equipment can continue labeling without stopping to re-load labels.