DAIRY PACK - RM40B

Jan 14, 2025, 09:31

Title :

DAIRY PACK - RM40B

Header :

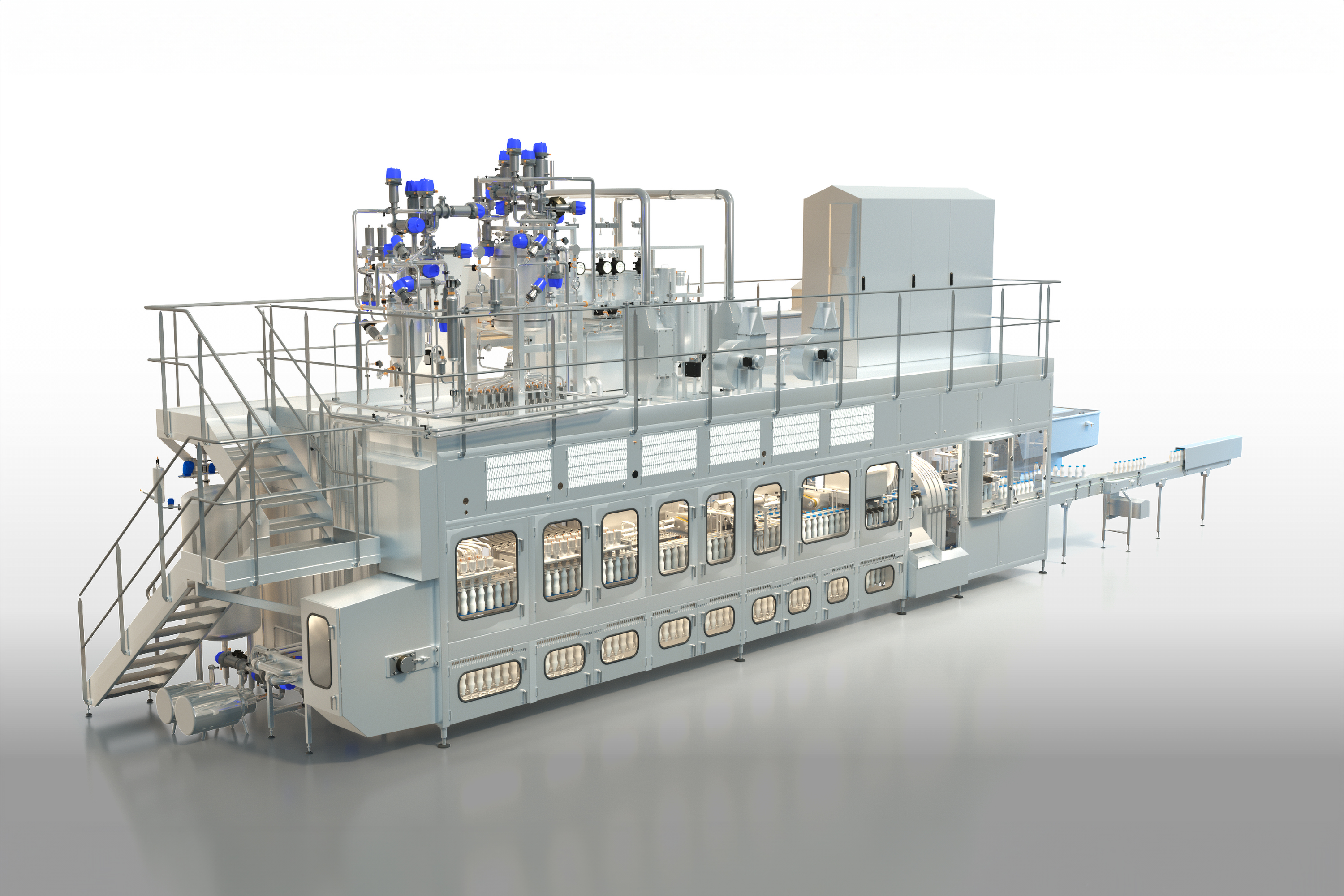

DAIRY PACK RM40B | MEDIUM OUTPUT INLINE BOTTLE FILLER

Hide from brand page :

No

Hide from product group page :

No

Order :

6

DAIRY PACK Bottle Filling Solutions

The RM40B is a compact and cost-efficient bottle filler, ideal for dairy beverage lines filling up to 12,000 bottles/hour, exists in “combi” with a bottle blower and can be extended to 24,000 bottles/hour in a RM80B configuration. DAIRY PACK RM80B is a wider version of the RM40B, adding a parallel line that doubles the output. All systems and technologies are common to both models and can be applied without reservation.

The Dairy Pack filling equipment is mainly used for dairy products and is available in a Combi configuration with a bottle blower. The Combi configuration combines blowing, filling, and capping for PET bottles.

The RM40B offers increased volume capacity and higher speeds. We can deliver a wide range of decontamination levels according to shelf-life needs and storage conditions. It benefits from Dairy Pack’s proven expertise built up over several years in filling complex products for large international groups.

Beverage Equipment for Your Recipes

Our RM40B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can also deliver a wide range of decontamination levels according to shelf-life needs and storage conditions. This machine's compact footprint and cost-efficiency are ideal for small beverage lines.

High Operational Efficiency

- Customizable speed up to 30 cycles per minute

- Production output up to 12,000 bottles/hour and 24,000 for the RM80B

- Filling various formats from 80 to 1500 ml

- Up to 2 different bottle neck diameters

- Materials: PET, HDPE, PP and PS

- Compliant with CE regulations

- Operations at chest height (110 cm/43.3 in)

Adapted to Sensitive Products

- Hygiene level adapted to your product specifications

- Suitable for most homogeneous and pumpable products with fruit pieces

- Synerlink offer a global commitment for hygenic, integrity and accuracy of the filled products.

- Fill testing available for customer product optimization and faster ramp-up

Compact with Easy Access & Cleaning

- Footprint (m) : 7 L x 4 W x 3 H

- Fast and efficient cleaning

- High visibility on stations and tooling

- High accessibility for inspections, maintenance and cleaning operations

- Customizable HMI visualization for optimized production reporting

- Output: up to 12,000 bottles/hour and 24,000 for the RM80B

- Pace: up to 30 cycles/min

- Dosed Product Range: 80 – 1,500 ml

- Material: PET, HDPE, PP and PS

- Compliant with CE regulations

Additional equipment will be integrated from selected suppliers who meet the same standards for quality and reliability. Suppliers of your choice can also be integrated, following a technical assessment.

Filters :

- 0-18,000 CPH

- A Zero to Three Thousand

- B Three to Five Point Four K

- Beverages

- Bottles

- C Five Point Four to Ten K

- Dairy (Yogurt, Cremas, Cheeses, Dairy Fats, etc.)

- Fill-Seal

- Inline

Related brands :

Dairy Pack

Related markets

Related embedded videos

Related locations

Related locations

Related machines

Related machines

Related packaging styles

Related form embeds :

BWFC Contact Us Form [Fill-Seal Machines]

Related testimonials :