HEMA - ACCES

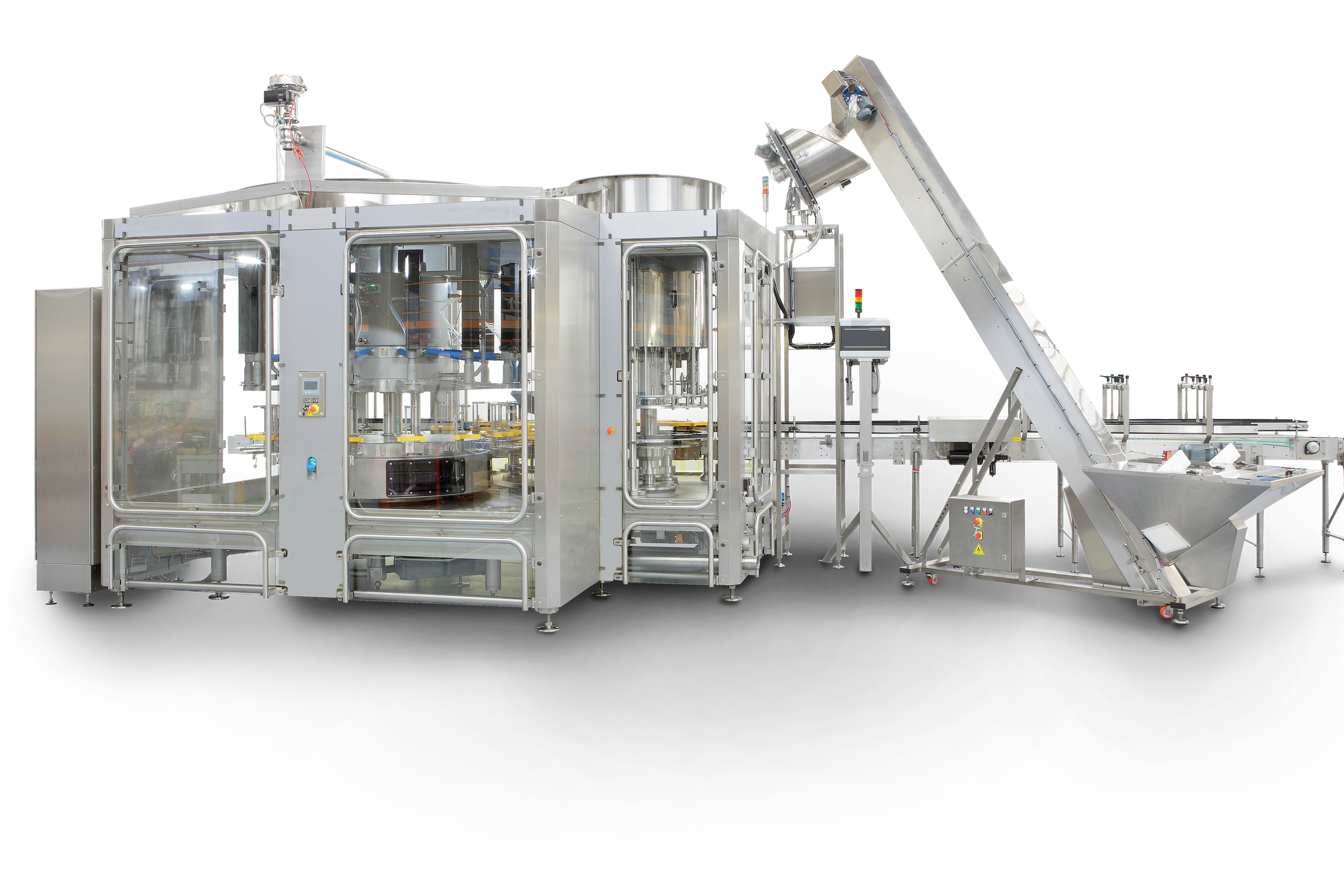

HEMA Electronic Edible Oil Rotary Filler

The ACCES filler series is dedicated to the edible oil market and has benefitted from Hema’s solid experience gained over several years of working for major International groups in the area of filling solutions for edible oil.

ACCES is available in Monobloc configuration with capper or Combi associating blowing, filling and capping for PET bottles.

We offer two packaging equipment filling technologies for edible oil: Weight – Mass Flow

Meeting Your Oil Filling Your Needs

Ensuring the correct handling of the product determines the shelf life and the quality of the edible oil. Whether it regards the oxidation or the product temperature. Edible oil producers are looking at solutions that can truly respond to this need while ensuring the packaging solidity.

Synerlink's Hema packaging equipment offers solutions that are studied to ensure your product shelf life and prevent oil oxidation. The right environment temperature, prevention of oxidation and strengthening bottle solidity for transportation are among the solutions that Synerlink offers to edible oil producers.

- Olive Oil

- Sunflower Oil

- Rape seed Oil

- Groundnut Oil

- Walnut Oil

- Palm Oil

HEMA ACCES Rotary Filler Features & Benefits

- Electronic filling technology reaching unequalled levels of filling accuracy for your edible oil product

- Hema packaging machine common frame for optimal hygiene

- Technical design which adapts to different electronic filling technologies: weight or mass flow

- Optimal filling capacity for all 2 technologies, in terms of production speed efficiency and optimal use of space.

- Common chassis design with a number of possible structures, allowing for the inclusion of numerous environmental options

- Wide doors, allowing easy access to the filling and capping zone for easy maintenance or tool changeover

- A reduced-sized hopper and off-centered nozzles, ensuring minimal product loss between recipe changes.

- Choose Hema ACCES, the Hema rotary filler machine, for precision and efficiency for your edible oil production

Production Flexibility

- The HEMA ACCES is designed for all types of edible oil filling - our patented double flap valve makes it possible to fill volumes from 80 ml to 5 liters at optimal speeds, without changing nozzles

- Up to 40,000 bottles per hour

- Recipes can be changed directly from the touchscreen control panel

- Accommodates containers in PET and Glass: Round, oval, with handle shapes, flat screw and push-pull caps

High Accuracy Dosing

- High filling precision: for 1L, Sigma<0,5g

- Unrivaled filling accuracy, set at low or high, according to the format of the bottle, the bottle-neck space and type of product

- EHEDG certified, IP69K load cell Modular Filler Configuration

- HEMA ACCES is available in a monoblock configuration with capper or the Combi configuration, which associates blowing, filling, and capping for PET bottles

- Number of filling heads : 15 to 66

- Number of capping heads : 5 to 22

- A common frame with several possible structures, allowing for the inclusion of numerous environmental options (N2 sparge or headspace gassing)

Fast Product Changeovers

- Quick, no-tool bottle format conversion

- Quick change nozzles

- Wide doors, allowing easy access to the filling and capping zone for easy maintenance or tool changeover

- ACCES electronic fillers are equipped with a smaller hopper and remote nozzles, ensuring minimal product loss between recipe changes

Easy Cleaning and Robust Design

- Non-contact valve technology prevents bottle-to-filler contamination

- Filler hygienic design with full stainless steel sloped frame

- An angular collecting trough collects the product at the end of production (optional)

- Low operating cost and easy maintenance

- Our goal is to design and deliver long-lasting solutions to our customers. No compromise on components and material quality are our best warranties

- Output: up to 40,000 containers/hour

- Number of filling heads : 15 to 66

- Number of capping heads : 5 to 22

- Dosed Product Range: 80 – 5,000 ml

- Compliant with CE regulations

Additional equipment will be integrated from selected suppliers who meet the same standards for quality and reliability. Suppliers of your choice can also be integrated, following a technical assessment.

- Bottles

- C Five Point Four to Ten K

- D Ten to Eighteen K

- E Eighteen to Twenty Four K

- F Twenty Four to Forty K

- Filler

- Fillers - Liquid and Viscous

- HEMA

- Net Weigh

- Net Weigh Filling

- Sauces, Dressings, Condiments, Edible Oils, Baby Food