HEMA - QCARE

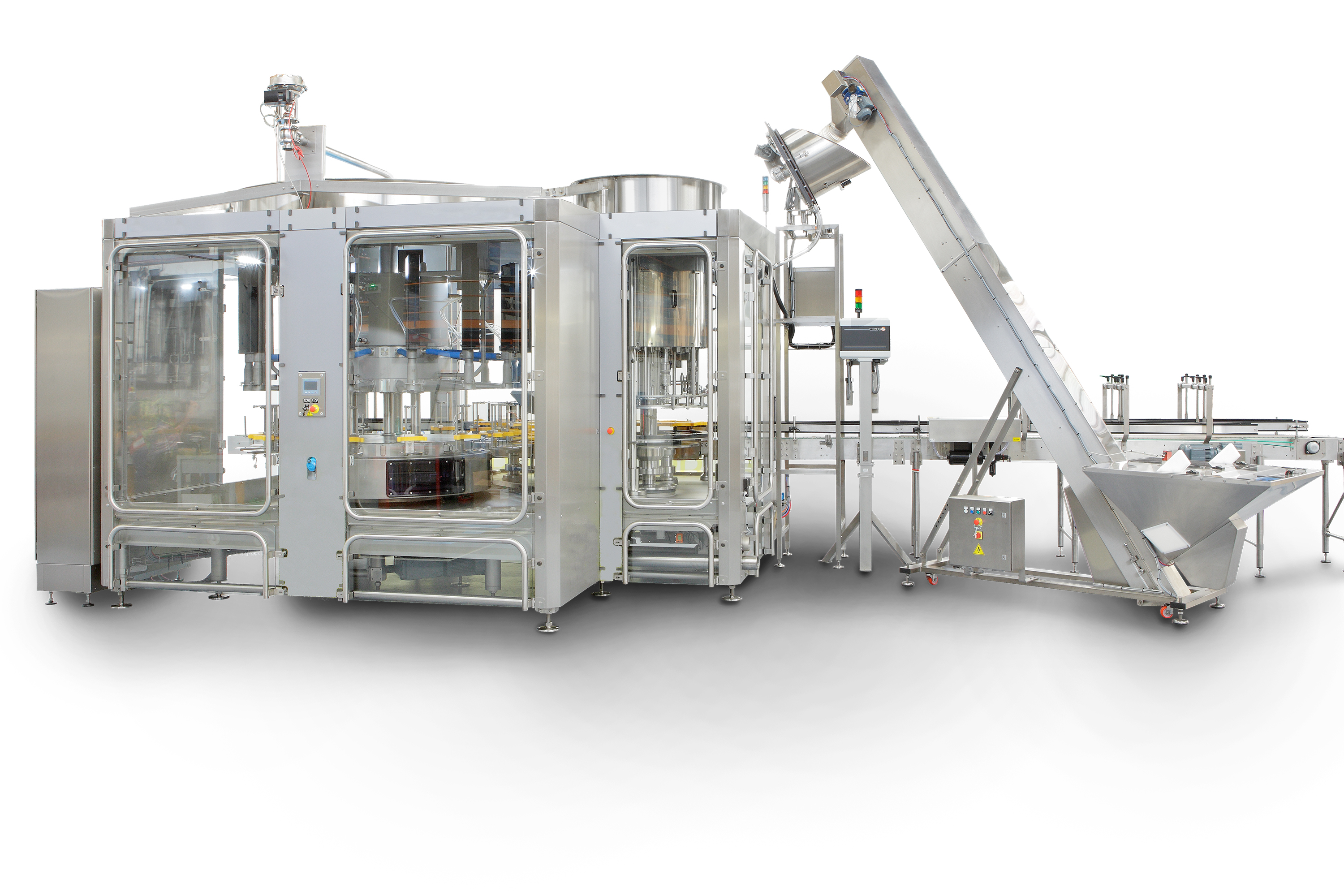

HEMA Electronic Rotary Filler

Hema QCARE is dedicated to the particulate and non-particulate Home and Personal Care market. It benefits from Hema’s proven expertise built up over several years, in the area of filling complex products for large international groups.

Hema QCARE is available in Monobloc configuration with capper or Combi associating blowing, filling and capping for PET bottles.

Hema QCARE fills:

- Shower gels

- Shampoo

- Dishwashing liquid

- Laundry and floor detergent

- Fabric Softener

Expertise with Experience

Home care and personal care producers usually handle various products as well as various packaging formats to fulfil their production and portfolio requirements. Obliging them to seek solutions that can respond to these needs while reaching all other production goals.

Hema integrated filling lines are conceived to help you reach your performance goals and are customized to your specific range of products. Our packaging equipment can handle several products on the same line with fast format changeover to respect your production needs in terms of quantity and in terms of product range.

We offer 2 filling technologies: Weight – Mass Flow

HEMA Rotary Filler Features & Benefits

- Hema Electronic filling technology reaching unequalled levels of filling accuracy

- Common frame for optimal hygiene

- Technical design which adapts to different electronic filling technologies: weight or mass flow

- Optimal filling capacity for all 2 technologies, in terms of production speed efficiency and optimal use of space.

- Common chassis design with a number of possible structures, allowing for the inclusion of numerous environmental options

- Wide doors, allowing easy access to the filling and capping zone for easy maintenance or tool changeover

- Hema packaging machines are equipped with a reduced-sized hopper and off-centered nozzles, ensuring minimal product loss between recipe changes.

Production Flexibility

- The HEMA QCARE is designed for all types of home and personal care products - our patented double flap valve makes it possible to fill volumes from 80 ml to 5 liters at optimal speeds, without changing nozzles

- 33 to 667 units/min, up to 40,000 bottles per hour

- Recipes can be changed directly from the touchscreen control panel

- Accommodates containers in PET and other plastics: Round, oval, with handle shapes, flat screw and push-pull caps

High Accuracy Dosing

- High filling precision: standard deviation < 0.5 grams for one liter for 1L, Sigma<0,5g

- Unrivaled filling accuracy, based on filling regulator speed, set at low or high, according to the packaging specifications and product special features

- By individually controlling the net weight of a product, every bottle that enters and exits the filling machine is checked

- The mass-flow filler is equipped with the latest checking technology and delivers clean product filling. The environment is hygienic, and the filling is precise, while keeping maintenance to a minimum

Modular Filler Configuration

Fast Product Changeovers

Easy Cleaning and Robust Design

- Output: up to 40,000 containers/hour

- Number of filling heads : 15 to 66

- Number of capping heads : 5 to 22

- Dosed Product Range: 80 – 5,000 ml

- Compliant with CE regulations

Additional equipment will be integrated from selected suppliers who meet the same standards for quality and reliability. Suppliers of your choice can also be integrated, following a technical assessment.

- Bottles

- C Five Point Four to Ten K

- D Ten to Eighteen K

- E Eighteen to Twenty Four K

- F Twenty Four to Forty K

- Filler

- Fillers - Liquid and Viscous

- HEMA

- HPC, Pharmaceutical, and Chemical

- Mass Flow

- Mass Flow Filling

- Net Weigh

- Net Weigh Filling