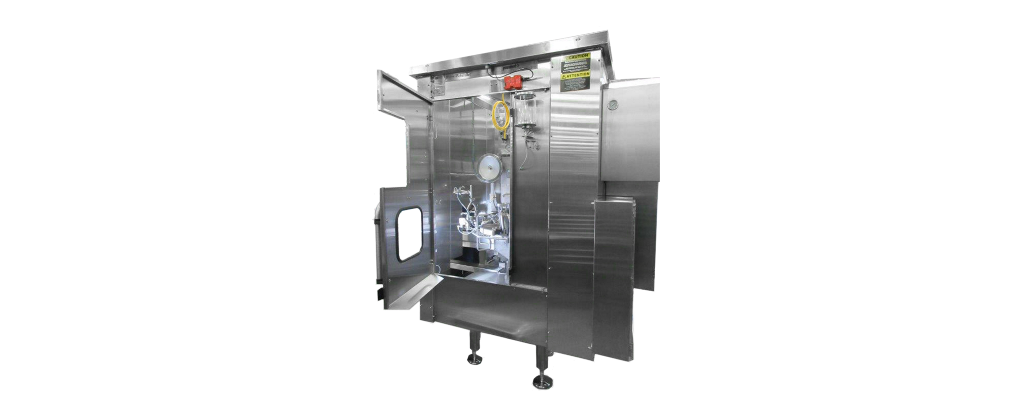

ANGELUS Legacy - 61H

Angelus seamers provide a hermetic seal by creating an airtight closure of five interlocked layers, three from the can end and two from the can body. The Legacy Series, as the name implies, carries on the tradition of reliability established when the Angelus Sanitary Can Machine Company was founded in 1910. Although an older design, we proudly continue to sell and service Legacy equipment.

The Angelus Legacy Series seamers, like the newer V-Series, incorporates a base-mounted stainless steel machine enclosure. The base-mounting provides precision and repeatability, while the stainless steel is durable and easy to clean. The Model 61H has six seaming stations and handles up to 600 Containers Per Minute (CPM). It is an oil-loss machine, rather than oil-recirculating.

Contact us today to speak with one of our Angelus experts about the specific requirements of your project. We’re happy to assist you.

- Runs at speeds of up to 600 Containers Per Minute (CPM)

- Six spindle seaming stations

- One set of can and end change parts

- Single roll cover separator

- Driven lower lifter oil pump system

- Automatic stop control system

- Leading industry PLC and HMI with touch screen control

- No can/no cover feed

- External warning safety horn and light

- Interlocking doors shut the machine off when opened for operator safety

- Comes with a tool kit and operators manual

- Seams cans between 200 – 404 (50.8- 108.0 mm) in diameter

- Seams cans between 110 - 800 (41.3-203.2 mm) high—Atmos & CM

- Seams cans between 111 -800 (41.3-203.2 mm) high—UCG & SV

- Transfer chain pitch is 5.50” (139.7 mm)

- Filler Drive is 1 Rev/Can (English) and Direction Reversible for Metric

- Electrical controls run on 24 VDC for both English and Metric systems

- Has a 15-20 HP motor (11-15kW)

- Dry air at base and upper turret housing is 3 psi (0.2 bar)

- CO² / Nitrogen Gas Supply Pressure is 100 psi @ 70F (6.9 bar @ 21C)

- CIP Cleaning—Hot Water Supply is 160F @ 60psi (71C @ 4.8 bar)

- CIP Cleaning—Steam Supply is 330F @ 85psi (165C @ 5.9 bar)

- Net weight is approximately 9200 lbs (4173 kg)

- Gross weight is approximately 10,300 lbs (4672 kg)

- Steam vacuum

- Under cover gassing

- Titanium Nitride-coated Angelloy® seaming rolls with ceramic bearings

- Titanium Nitride-coated Angelloy® seaming chucks

- Quick set seaming can

- Random infeed

- Filler connecting parts

- Cover feed chute with vibrator

- Magnetic downstacker chute with vibrator

- Nickel-plated machine

- Hot water automatic seamer washdown

- Recipe motorized turret height elevating mechanism