RECOMMENDED: ANGELUS V-Series - 4V

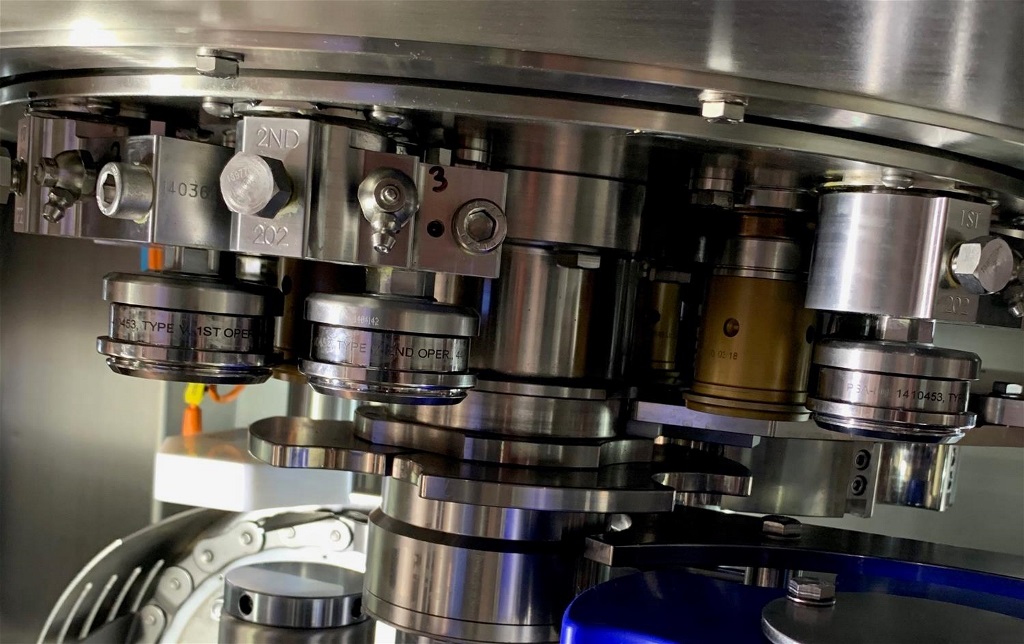

Angelus seamers are designed specifically for food and beverage processors. They provide a hermetic seal by creating an airtight closure of five interlocked layers, three from the can end and two from the can body.

The Angelus V-Series seamer contains 25% fewer components than traditional Angelus seamers, and employs an 80% parts commonality across the family. They support the technologies, including atmospheric, under cover gassing, steam vacuum and liquid Nitrogen dosing that are used in the most challenging applications. The Model 4V has four seaming stations, and can seam 100 - 450 containers per minute (CPM).

The metric, base-driven design is built with an excellent pitch match with today’s modern fillers. The 304 stainless steel used in all product contact areas ensures a clean, sanitary design that is foam and chemical cleaning-compatible, making it ideal for food and beverage markets.

Contact us today to speak with one of our Angelus experts about the specific requirements of your project. We’re happy to assist you.

- Runs at speeds up to 100 - 450 Containers Per Minute (CPM)

- Provided in either mechanical filler connection or servo synchro

- New and improved driven lower lifters

- Motorized turret height adjustment with digital readout

- TN-coated Angelloy® seaming rolls with ceramic bearings

- Easy-adjust chuck plate springs keep downtime to a minimum

- Industry-standard PLC and HMI controls pilot devises and E-Stop

- NEMA 12 electrical enclosure (standalone), with lockable disconnect ensures operator safety

- NEMA 4X junction box is machine mounted and integrated into guarding

- Under cover gassing control with variable valve for use in seaming beverages

- Ancillary systems are integrated into the guarding enclosure

- Vibration isolation pads on seamer legs

- Comes with basic tool kit

- Cone drive main gearbox

- Mechanical filler connection with cardan shaft

- Seams cans between 200 - 401 (50.8-103.2 mm) in diameter

- Seams cans between 113-800 (46-203.2mm) high

- Transfer chain pitch is 6.46” (164.08 mm)

- Recirculated oil provides the lubrication

- Has a 230/380/400/460 volt, 3 phase, 50/60 hertz motor, with 24 VDC control voltage

Angelus V-Series Models Comparative Table

Model | Speed Range | Seaming Stations | Stainless Steel | Lubrication | Min/Max Can Diameter (in) | Min/Max Can Diameter (mm) | Min/Max Can Height (in) | Min/Max Can Height (mm) | Transfer Chain Pitch (in) | Transfer Chain Pitch (mm) | Application |

18V | 500-2500 | 18 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.562 or 3.666 | 90.5 or 93.1 | Beverage |

12V | 400 - 1800 | 12 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.562 or 3.666 | 90.5 or 93.1 | Beverage |

9V | 300 - 1200 | 9 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 4.75 | 120.7 | Food and Beverage |

8V | 250 - 1000 | 8 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.876 | 98.45 | Food and Beverage |

6V | 175 - 700 | 6 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 5.168 | 131.27 | Food and Beverage |

4V | 100 - 450 | 4 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 6.46 | 164.08 | Food and Beverage |

3V | 75 - 350 | 3 | Standard | Oil Recirculation | 401 to 603 | 103.2 to 157.2 | 113 to 901 | 41.3 to 244.5 | 10.336 | 262.53 | Food and Beverage |

1V | 10 to 15 | 1 | Standard | Grease | 201 to 300 | 50.8 to 157.2 | 110 to 901 | 41.3 to 244.5 | Random Timing | N/A | Beverage |

1V | 10 to 30 or 30 to 50 | 1 | Standard | Grease | 201 to 603 | 50.8 to 157.2 | 110 to 901 | 41.3 to 244.5 | Random Timing | N/A | Food |

- Optional servo filler drive will sync with main motor bottom drive

- Choose between Chrome-plated steel or Ceram P® filler discharge and seamer infeed transfer wear plates

- Vibration isolation pads, standard on the seamer legs, can have lagging to the floor if needed

- 0-13,500 CPH (0-225 CPM)

- 0-15,000 CPH (0-250CPM)

- 13,500-24,000 CPH (225-400 CPM)

- 15,000-24,000 CPH (250-400 CPM)

- 24,000-42,000 CPH (400-700CPM)

- ANGELUS

- ANGELUS V-Series

- C Five Point Four to Ten K

- Cans

- D Ten to Eighteen K

- Dairy (Yogurt, Cremas, Cheeses, Dairy Fats, etc.)

- Dry or Powdered Products

- E Eighteen to Twenty Four K

- F Twenty Four to Forty K

- Food & Other

- Fruits and Vegetables

- HPC, Pharmaceutical, and Chemical

- Meat and Fish-Based Products

- Sauces, Dressings, Condiments, Edible Oils, Baby Food

- Seamers

- Sweetened Products