ANGELUS Legacy Series: Model 40P

About this machine

About this technology

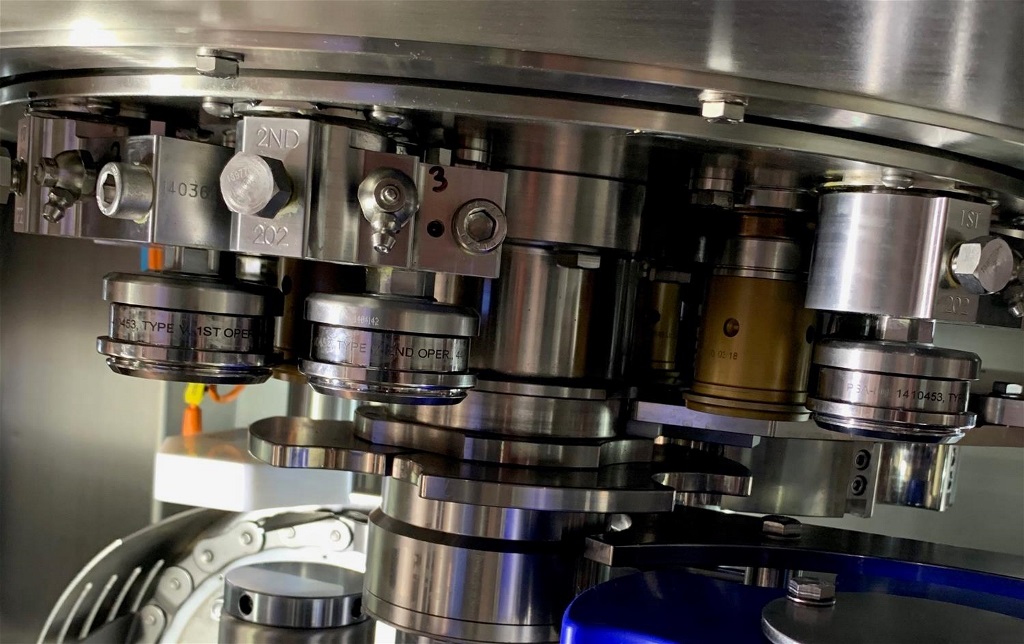

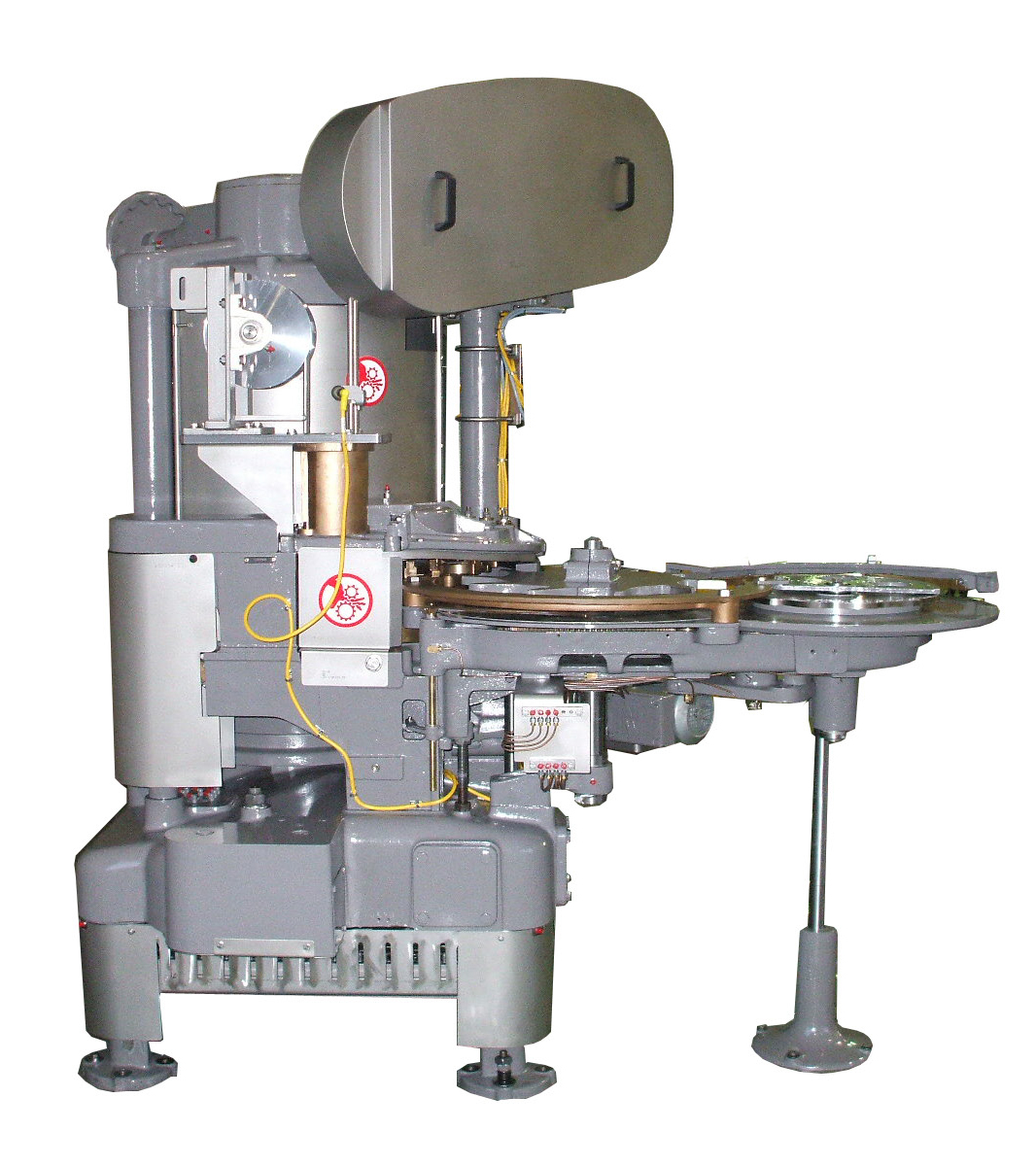

Angelus seamers provide a hermetic seal by creating an airtight closure of five interlocked layers, three from the can end and two from the can body. The Legacy Series, as the name implies, carries on the tradition of reliability established when the Angelus Sanitary Can Machine Company was founded in 1910. Although an older design, we proudly continue to sell and service Legacy equipment.

The Angelus Legacy Series seamers, like the newer V-Series, are built of stainless steel for durability and ease of cleaning. This unit has a free-standing machine enclosure. It has door interlocks which stop the machine when opened, for added operator safety. The Model 40P has a 4-head rotary seaming turret and handles up to 275 Containers Per Minute (CPM).

Contact us today to speak with one of our Angelus experts about the specific requirements of your project. We’re happy to assist you.

Product Details

Runs at speeds of 275 Containers Per Minute (CPM)

4-head rotary seaming turret

Built for easy operation and maintenance

Variable speed motor drive

One set of can and end change parts

No can/no cover feed

Grease lubrication

Electric brake

Disc feed infeed

Comes with a tool kit and operators manual

Technical Data

Seams cans between 2-2/16" - 4-4/16" (54 - 108 mm) in diameter

Seams cans between 1-8/16"-- 7" (38.1-177.8 mm) high

Maximum Side Lap Forged (MSLF) overlap Seams between 1-11/16" - 7" (42.9- 177.8 mm) high- SV and UCD

The Double Flange (DF) for SF & UCG) is between 1-11/16 - 7" (42.9- 177.8 mm) high

Transfer chain pitch for MLSF is 6" (152.4 mm)

Transfer chain pitch for DF is Random for both English and Metric systems

Electrical controls run on 24 DC for both English and Metric systems

Has a 5 HP motor (4 kW)

CO²/ Nitrogen Gas at 100 psi at 70F (or 6.9 bar at 21C)

Steam supply is 330psi @ 85 F (5.9 bar @ 165C)

Net weight is approximately 5,900 lbs (2,676 kg)

Gross weight (Domestic) MSLF is approximately 6,900 lbs (3,130 kg)

Gross weight (Export) MSLF is approximately 7,300 lbs (3,311 kg)

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

4485 Allen Rd

Stow OH 44224

US -

+1 (800) 992 0491

-

10 Ascot Pkwy

Cuyahoga Falls OH 44223

US -

+1 (800) 992-0491

-

De Salis Drive

Droitwich WR9 0QE

GB -

+44 01905 779602

-

Plumtree Farm Industrial Estate, Plumtree Road, Bircotes

Doncaster DN11 8EW

GB -

+ 44 (0) 1302 718353

-

Via Mercall, 16/A

Parma 43122

IT -

+39 0521 795601

-

Unit 4, 13th Floor, Block A; Po Yip Building; 62-70 Texaco Road

Tsuen Wan, N.T., Hong Kong

CN -

+85 2 2215 3622

-

F7 13-15 Forrester St

Kingsgrove NSW 2208

AU -

+61 02 9150 7055

Markets

Markets