ANGELUS V-Series: Model 6V

.png?sfvrsn=b2b1555f_1)

About this machine

About this technology

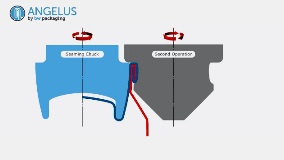

Angelus seamers are designed specifically for food and beverage processors. They provide a hermetic seal by creating an airtight closure of five interlocked layers, three from the can end and two from the can body.

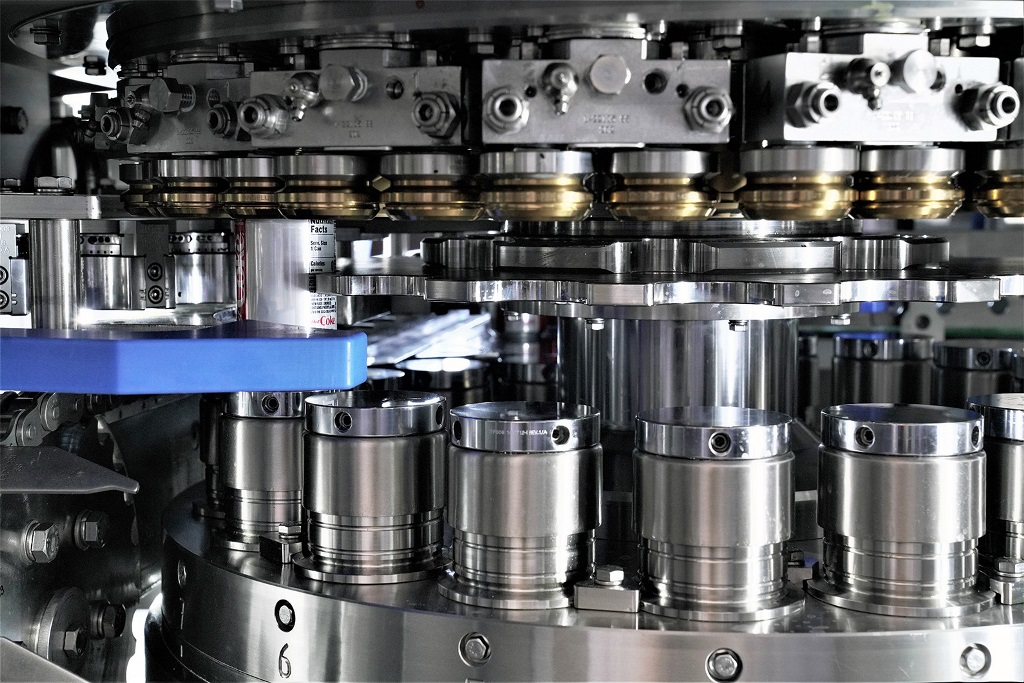

The Angelus V-Series seamer contains 25% fewer components than traditional Angelus seamers, and employs an 80% parts commonality across the family. They support the technologies, including atmospheric, under cover gassing, steam vacuum and liquid Nitrogen dosing that are used in the most challenging applications. The Model 6V has six seaming stations, and can seam 175 -700 containers per minute (CPM).

The metric, base-driven design is built with an excellent pitch match with today’s modern fillers. The 304 stainless steel used in all product contact areas ensures a clean, sanitary design that is foam and chemical cleaning-compatible, making it ideal for food and beverage markets.

Contact us today to speak with one of our Angelus experts about the specific requirements of your project. We’re happy to assist you.

Product Details

- Runs at speeds up to 175 -700 Containers Per Minute (CPM)

- Provided in either mechanical filler connection or servo synchro

- New and improved driven lower lifters

- Motorized turret height adjustment with digital readout

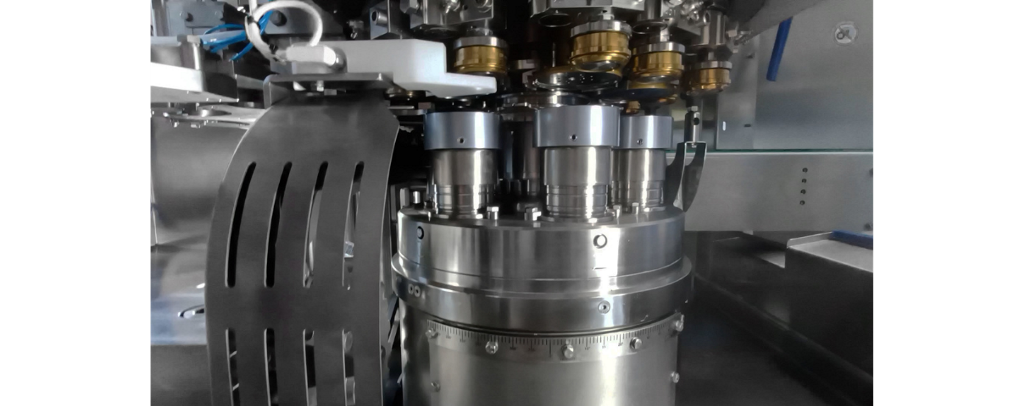

- TN-coated Angelloy® seaming rolls with ceramic bearings

- Easy-adjust chuck plate springs keep downtime to a minimum

- Industry-standard PLC and HMI controls pilot devises and E-Stop

- NEMA 12 electrical enclosure (standalone), with lockable disconnect ensures operator safety

- NEMA 4X junction box is machine mounted and integrated into guarding

- Under cover gassing control with variable valve for use in seaming beverages

- Ancillary systems are integrated into the guarding enclosure

- Vibration isolation pads on seamer legs

- Comes with basic tool kit

Technical Data

- Cone drive main gearbox

- Mechanical filler connection with cardan shaft

- Seams cans between 200 - 401 (50.8-103.2 mm) in diameter

- Seams cans between 113-800 (46-203.2mm) high

- Transfer chain pitch is 5.168” 131.27 mm)

- Recirculated oil provides the lubrication

- Has a 230/380/400/460 volt, 3 phase, 50/60 hertz motor, with 24 VDC control voltage

Model | Speed Range | Seaming Stations | Stainless Steel | Lubrication | Min/Max Can Diameter (in) | Min/Max Can Diameter (mm) | Min/Max Can Height (in) | Min/Max Can Height (mm) | Transfer Chain Pitch (in) | Transfer Chain Pitch (mm) | Application |

18V | 500-2500 | 18 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.562 or 3.666 | 90.5 or 93.1 | Beverage |

12V | 400 - 1800 | 12 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.562 or 3.666 | 90.5 or 93.1 | Beverage |

9V | 300 - 1200 | 9 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 4.75 | 120.7 | Food and Beverage |

8V | 250 - 1000 | 8 | Standard | Oil Recirculation | 200 to 300 | 50.8 to 76.2 | 113 to 800 | 46.0 to 203.2 | 3.876 | 98.45 | Food and Beverage |

6V | 175 - 700 | 6 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 5.168 | 131.27 | Food and Beverage |

4V | 100 - 450 | 4 | Standard | Oil Recirculation | 200 to 401 | 50.8 to 103.2 | 113 to 800 | 46.0 to 203.2 | 6.46 | 164.08 | Food and Beverage |

3V | 75 - 350 | 3 | Standard | Oil Recirculation | 401 to 603 | 103.2 to 157.2 | 113 to 910 | 41.3 to 244.5 | 10.336 | 262.53 | Food and Beverage |

1V | 10 to 15 | 1 | Standard | Grease | 201 to 300 | 50.8 to 157.2 | 110 to 910 | 41.3 to 244.5 | Random Timing | N/A | Beverage |

1V | 10 to 30 or 30 to 50 | 1 | Standard | Grease | 201 to 603 | 50.8 to 157.2 | 110 to 910 | 41.3 to 244.5 | Random Timing | N/A | Food |

Packaging Styles

Videos

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

10 Ascot Pkwy

Cuyahoga Falls OH 44223

US -

+1 (800) 992-0491

-

Via Mercall, 16/A

Parma 43122

IT -

+39 0521 795601

-

De Salis Drive

Droitwich WR9 0QE

GB -

+44 01905 779602

-

Plumtree Farm Industrial Estate, Plumtree Road, Bircotes

Doncaster DN11 8EW

GB -

+ 44 (0) 1302 718353

-

Office 104, Building 20B, 2388 Chenhang Highway

Minhang District, Shanghai

CN -

+86 21 6252 5685

-

Unit 4, 13th Floor, Block A; Po Yip Building; 62-70 Texaco Road

Tsuen Wan, N.T., Hong Kong

CN -

+85 2 2215 3622

-

Room 1801, Peace Business Center, No. 880 South Guangzhou Avenue

Haizhu District, Guangzhou, Guangdong Province 510300

CN -

+ 86 20 3801 0570

-

F7 13-15 Forrester St

Kingsgrove NSW 2208

AU -

+61 02 9150 7055

Markets

Markets